Description

Railroad Short Name: UP

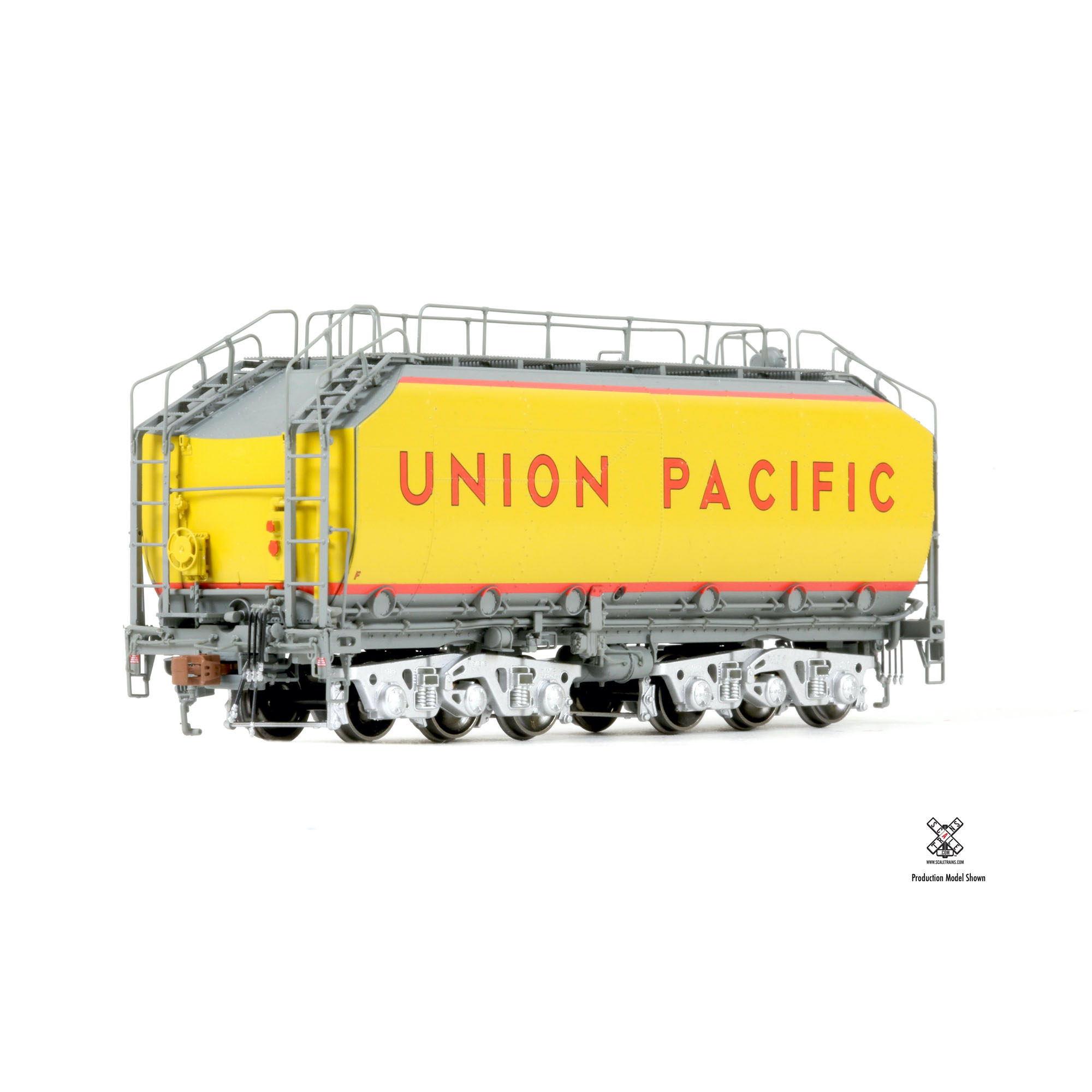

Equipped with a massive GE turbine engine, the “Big Blow” Super Turbines had a prodigious appetite for fuel. In order to provide for a suitable operating range, as well as allow for the unique physical properties of the Bunker C heavy fuel oil (basically tar) they were designed to burn in road operation, retired UP steam tenders were rebuilt and re-purposed for the GTEL program, resulting in two distinctive different classes that operated behind the Big Blows.

The un-insulated 23-C-GTEL tenders were rebuilt from 19-C steam engine tenders salvaged from retired 3800 Class 4-6-6-4 Challenger locomotives. With a capacity of 23,000 gallons of fuel oil, these tenders are recognizable by their exterior riveting, and the round heater details protruding along the bottom of the body. Operating on “Buckeye” cast trucks, these short tenders had a “stubby” appearance.

The longer, insulated 24-C-GTEL tenders were rebuilt from 20-C steam engine tenders salvaged from retired FEF-1 Class 4-8-4 Northern locomotives. With a capacity of 24,000 gallons of fuel oil, these tenders had a layer of insulation and sheet metal jacketing applied when rebuilt for use with the “Big Blow” Super Turbines, giving them a smooth, clean appearance. The internal heater elements, required to help keep the thick Bunker-C fuel viscous, were located behind the round access plates bolted to the sides of the lower body.

Throughout the service lives of the “Big Blow” Super Turbines, it wasn’t uncommon for tenders to be swapped and renumbered among sets as maintenance dictated, so it was very possible to see a Big Blow set originally delivered with a 23C tender operating with a 24C tender later in its career, and vice-versa.

- Fully assembled

- 24-C-GTEL Class riveted body

- 24,000-gallon capacity

- Riveted seams

- Photo-etched metal tender deck walkway

- Intricate electrical and water plumbing

- Factory-applied air tank, brake cylinder, and control valve

- Brake beam

- Handbrake housing with finely detailed wheel and chain

- Factory-applied multiple unit (MU) hoses, coupler cut levers, and trainline hoses

- Durable body-mounted die-cast metal semi-scale Type E knuckle couplers

- Buckeye 3-axle trucks with SKF bearings

- 36” machined metal wheels

- Accurately profiled .110″ wide wheel tread

- Operating rear tender LED light

- 2-function DCC programmable decoder

- Operate using DC and DCC

- Operates on Code 70, 83 and 100 rail

- Truck safety chains available separately (SXT80111) – requires 22” minimum radius curve

- Printing and lettering legible even under magnification

- Color matched to Tru-Color paint

- Weighted above Industry standards

- Packaging safely stores model

- Minimum radius: 18”

Reviews

There are no reviews yet.