Description

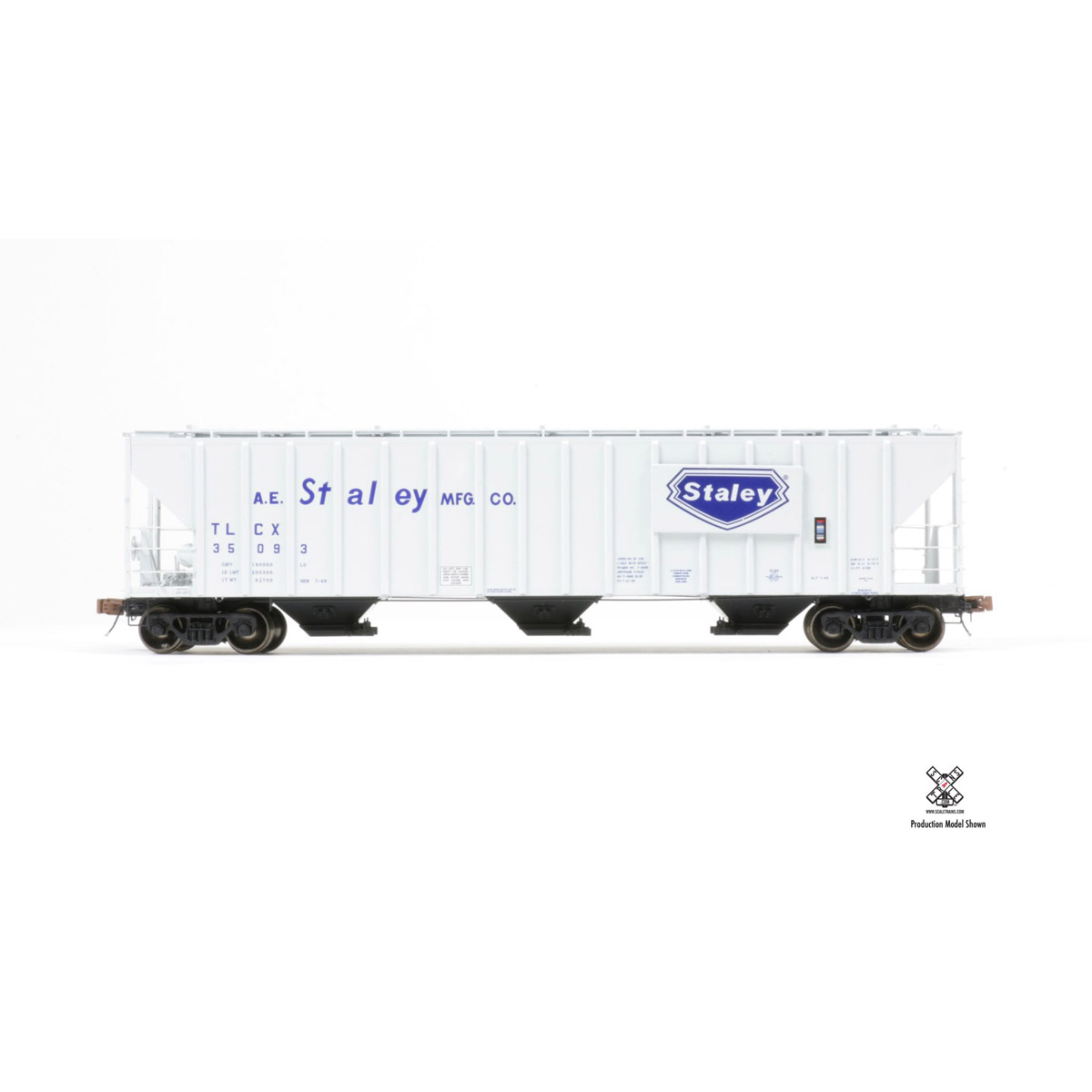

Railroad Short Name: Staley

Perfect for modelers from the 1960s until today, these cars are an important part of the P-S covered hopper family. Since the beginning, these cars have crisscrossed North America running in groups and singles in freight trains. These models feature numerous roof hatch, outlet gate, running board, and end “cage” support variations per roadname and production group.

- As-built paint and configuration

- TLCX 35030-35114, built 1969 (P-S Lot 9427)

- Equipped with short-track gravity outlets

- Equipped with long trough loading hatches

- Short angled end grab supports with long center sills

- Handbrake on short angled end supports

- Apex (slotted) running boards and coupler platforms

- Separately-applied photo-etched “Staley” logo placard

- Features ACI labels applied to raised “boxes” on car sides

- Examples lasted into the 1990s in their as-built paint

Additional Features

- All-new model

- Four (4) different road numbers for Conrail, Penn Central, Cotton Belt, and Staley

- Two (2) different road numbers for Cargill and Highland Feeders

- Multiple roof hatch options, per prototype: Continuous Trough, 3-Trough, or Round Hatch – see roadname above for specific version

- Apex (slotted), Morton (round-hole), or U.S. Gypsum (diamond-hole) walkways and coupler platforms – see roadname above for specific version

- Photo-etched stainless steel see-through running board with metal grab irons

- Photo-etched stainless steel see-through end crossover platforms

- Multiple end brace and grab variations– see roadname above for specific version

- Multiple “end cage” grab iron and support configurations – see roadname above for specific version Gravity or Gravity-Pneumatic outlets – see roadname above for specific version

- End shear plates – denoted as appropriate by roadname above

- Factory-applied ladders with metal rungs

- Factory-applied trainline pipe

- Brake plumbing with separate air reservoir, control valve, and retainer valve details plus separately applied wireform plumbing.

- Handbrakes mounted to stands, end supports, and or end shear plate – see roadname above for specific version

- Durable die-cast metal semi-scale standard Type E couplers

- Highly-detailed Barber S-2 100-ton trucks with finely rendered raised foundry data, rotating bearing caps, side bearing detail, and truck-mounted brake beams

- 36” machined metal wheels

- Minimum radius: 18”

- Recommended radius: 22”

All Rivet Counter Freight Cars Feature

- Fully assembled

- Factory-applied metal grab irons

- Factory-applied coupler cut levers

- Trainline hoses

- Intricate brake plumbing

- Printing and lettering legible even under magnification

- Color matched to existing Tru-Color Paint colors whenever possible

- Accurately profiled .110″ wide wheel tread

- Weighted to Industry standards for reliable operation

- Operates on Code 70, 83 and 100 rail

- Packaging safely stores model

Reviews

There are no reviews yet.